|

A workshop cool plate |

This is a description of a flat plate which can be heated and cooled under computer control, between 5 °C and 40 °C. It can be used for conservation treatments as well as for experiments exploring the behaviour of materials during temperature change.

Treatments involving heating the object are commonly used by conservators. Treatments involving cooling the object are unusual, because of the relative expense and rarity of the apparatus. However, the rapid development of the 'internet of things' has brought down the expense of the sensors and processors needed to control devices. The apparatus described in this article cost about 100 euro in processor and sensors. The other development encouraging us to present an apparently complex device as a do-it-yourself exercise, is the 'Fabrication Laboratories' (FabLabs) movement, which provides advice and help in construction to ordinary people with an idea but not the skill to complete the project without help.

The most useful cool temperature during conservation is between ambient and the dew point of the room. It is possible to control the local RH subtly enough to produce a softening of the material without wetting it. A specimen held at a temperature just above the dew point will equilibrate to a very high RH, say 95%, without ever getting wet.

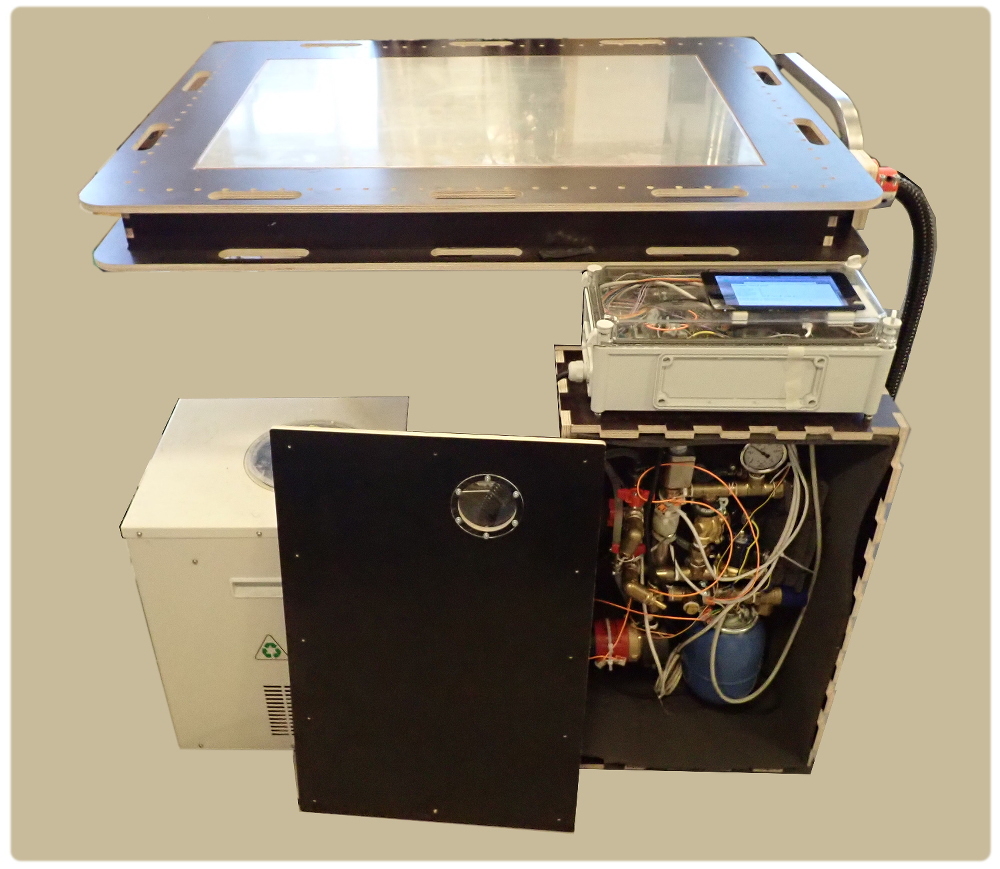

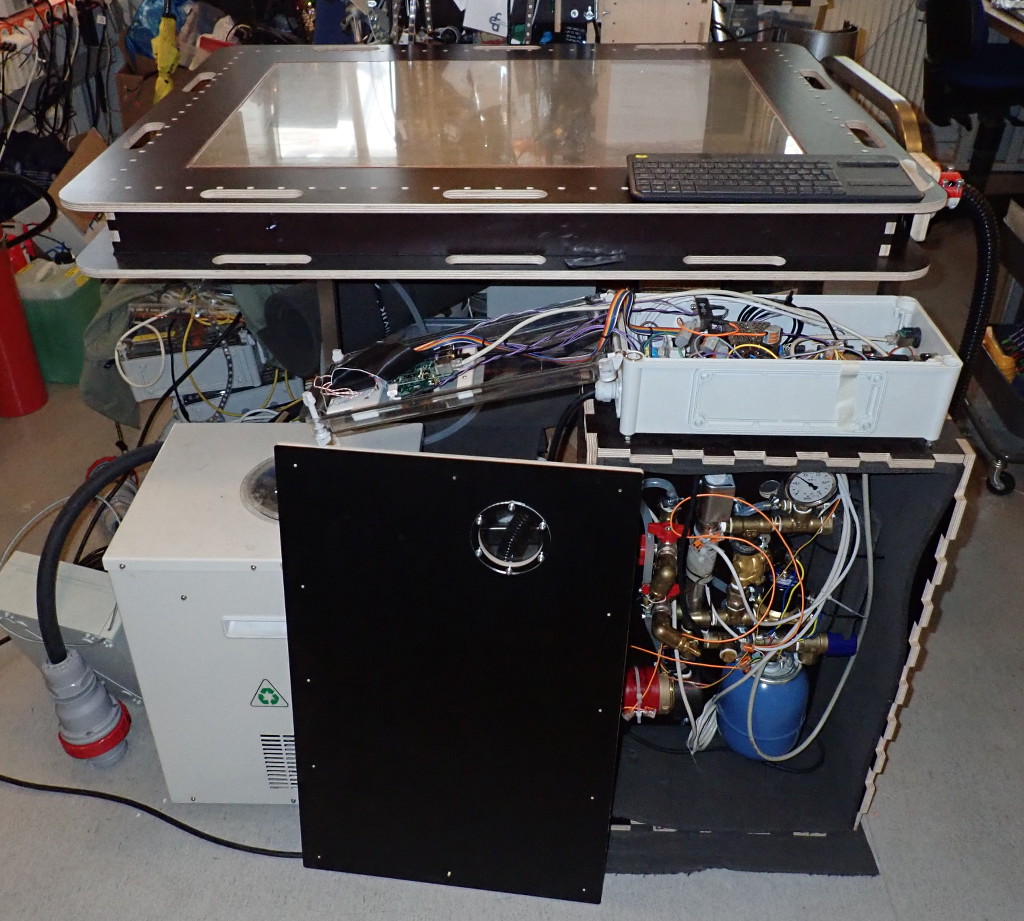

The cool plate apparatus with the components separated. The cooler is at bottom left, the plumbing which adjusts the water temperature to the plate is exposed at bottom right. On top of this is the control panel with touch screen and raspberry pi micro-computer. Shielded flexible hoses send water through the plate, which can be set in any orientation.

The apparatus is designed to be energy efficient compared with a typical laboratory controlled temperature water bath which usually heats against a continuously working cooling unit. This cool plate is more complicated in its plumbing because it switches between heating, doing nothing and cooling, without fighting hot against cold all the time.

Condensation of water from the ambient space is liable to accumulate on parts of the apparatus. Condensation is minimised by making all the parts airtight and by providing insulation and humidity buffering, as described later.

When the cool plate temperature is set just above the ambient dew point, it will generate a high local RH at the surface of an object laid upon it, say 95%. This allows manipulation to reduce distortion in water colour paper, for example, without actually wetting it. If a gentle wetting is required, the plate can be set at a temperature just below the dew point, so that condensation settles imperceptibly on the object. For three dimensional objects, an insulated cover is set over the plate, so that the entire volume attains a high RH. This cover can be provided with sealed in gloves to allow manipulation at high RH.

In the other direction, drying artefacts to exact equilibrium with the ambient relative humidity can be achieved by setting the plate temperature just above the temperature of the surface of the damp object resting upon it. As the object dries, its surface temperature, kept cool by evaporation, gradually rises to that of the ambient air. The plate temperature can be adjusted gradually to equal the ambient temperature as this equilibrium becomes established. This process is described in detail here

This process requires measuring the ambient and the surface temperature so that the operator can adjust the plate temperature. Alternatively, a datalogger can automatically send a temperature instruction to the cool plate in the form of a web page URL. This provides a degree of automation of the drying process.

The flat plate sitting flush within its frame makes it easy to set up experiments, compared with working within a small climate controlled chamber. It is easy to make stress-strain measurements on canvas stretched across the plate. The climate within an enclosed picture in a glazed frame set in a varying temperature gradient typical of an outside wall of a historic building, has not yet been satisfactorily investigated, resulting in strange 'intuitive' practices such as cutting off the corners of a backboard to let the painting 'breathe'. The plate can be set in any orientation, to imitate a wall surface, a ceiling or a floor.

Current demands, embedded in severe loan contracts, for climate stability around borrowed artefacts can be compared with objectively measured effects on dimensions and stiffness.

There are interesting questions about the rate of emission of volatile pollutants from artefacts. The rate of diffusion within the object is a temperature dependent process, but so also is the rate of generation of pollutants from chemical reactions within the artefact. This double dependence on temperature results in a remarkably large reduction in the measured pollution in cool storage rooms, as measured by Morten Ryhl-Svendsen: www.conservationphysics.org/storage/low-energy_museum_storage_buildings.pdf. This is important to the design of storage rooms, particularly for photographs and other modern materials of doubtful durability. Accurate quantitative experiments are needed to confirm the empirically measured concentrations from existing storage rooms.

Experimental measurements will usually be made by observation or by a data logger. The plate temperature control is kept separate from data logging of an experiment, to ensure safe operation. However, there will be operations, as described above, where the temperature needs to be actively adjusted by the experimental process, without human intervention.

For this interaction there is an API (Applications Programming Interface) in the form of a web page address (URL) which allows a separate computer or data logger which is connected to the internet, or to the local area network (LAN) to adjust the temperature of the plate. This URL sends the required temperature, the web server checks the validity of the new instruction and returns a success code. If invalid parameters are submitted, the plate issues a warning and continues to operate as before.

The apparatus has been designed with care to function in collaboration with both humans and automatic data loggers. Its versatility goes far beyond the standard laboratory hot plates and cold water baths. The design is open source and the digital control system is also open source. We have used easily available items and the minimum of unique computer code.

The plate is A1 size (841 x 595 mm), 10 mm thick aluminium. It is set flush within a plywood frame with dimensions 1130 x 880 mm. The plate is grooved on the back side to take a grid of copper tubing, 8 mm OD. The tubing is held down to the plate by a set of aluminium L-sections bolted to the plate between the grooves. Thermal expansion is accommodated, and electrolytic corrosion is impeded, by a neoprene membrane between the aluminium beams and the copper tubing.

The plate temperature is measured in two places by platinum resistance sensors spring-mounted flat against the plate.

A back view of the aluminium plate with a net of copper pipes held against it by cross-girders. The white stain is thermal conductive paste.

There is a thin layer of silica gel buffer grains behind the plate to prevent condensation when the plate is below the dew point of the air within the enclosure. On top of that is rockwool insulation.

The copper pipe net is covered with a thin layer of yellow silica gel, then a permeable membrane and finally mineral wool insulation. The back is sealed by the flexible draught stopper. Note the plugs mounted near opposite corners, for flushing the interior with dry air if condensation occurs.

The fully insulated plate with the backplate ready to screw down.

The front of the plate is sealed flexibly into its frame by "sicaflex" polyurethane sealant on a backing of neoprene foam. This allows for thermal movement.

The aluminium plate can be coated with paint to increase its radiant energy exchange. The broad flat frame allows experimental equipment to be mounted and also allows placing insulation to minimise edge effects.

The apparatus with the workings exposed. The water circulation system box supports the control electronics, shown hinged open with the computer and screen on the left and the power supplies and circuit boards on the right.

The control box is governed by a raspberry pi computer. The physical connections are shown in the linked pdf. The setup and programming of both the web server and the temperature control program is described in the complete set of scripts (tar archive)

The raspberry pi has a small touch display and a wireless keyboard with pad for direct communication. Instructions are sent, and the results are displayed, on a web page, which can also be viewed and used remotely. How to do this depends on the security arrangements of the institution, so instructions will vary from site to site.

The coolplate can be set to control its temperature at a constant value or at a value which changes in a sine wave, a triangular wave or a square wave. The amplitude and period of these waves can be set.

Some procedures require that an external data processor must adjust the plate temperature automatically. This can be done by sending a temperature instruction as a URL.

The reaction time of the control circuit can be adjusted. There is a PID controller (Proportional-Integral-Derivative) which adjusts its approach to the set point so that it does not overshoot or oscillate. Some experiments present a greater inertia to temperature change, so may need fine tuning of the coefficients of the PID controller.

This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.