|

Choosing where to mount sensors |

The sensor should be out of the direct beam from spotlights, away from sources of radiant heat, or cold, such as windows and poorly insulated outside walls. It should not be in the flow of convective air from a radiator. It should not be in the direct path of air blown in from an air conditioning duct. It should not at any time be illuminated by direct sunlight. It should not even be placed on a wall above a part of the wall that can be illuminated by direct sunlight. It should be at about head height, definitely not in the half meter just below the ceiling, where the temperature can be higher than at exhibit level. It should be out of easy reach. Given these restrictions it is often surprisingly difficult to find a place to fix the sensor!

The moisture content of the air in a room is usually uniform. Variation in relative humidity is usually caused by temperature variation from place to place. In a large room with several microenvironments caused by elaborate exhibition structures it may be advisable to measure in several places. However, it may only be necessary to measure the temperature, using a single RH sensor at one measuring spot as a basis for calculating the probable RH at the other places. This is certainly true in air-conditioned buildings and can anyway be tested by temporarily installing several combined RH and temperature measuring points.

Air circulation is often bad in store rooms, because they eventually become fuller than planned. The most economic way to measure the climate is to place temperature and relative humidity sensors in the most open, central space available and then place a second temperature sensor at the place in the store that is worst ventilated, worst insulated, most exposed to outside temperature or maybe influenced by a hot equipment room through an uninsulated wall.

Placing multiple sensors might seem over elaborate but can have surprisingly beneficial consequences. The most usual consequence is that the climate is found to be very uniform, because the engineer (we are talking about modern institutional buildings) was terrified of legal action if the room did not meet the specification set by the client, who had passed to the engineer the specification set by the institution's conservator, who in turn specified strict limits because she did not know the economic consequences of doing so.

The result of this interdisciplinary exercise, meaning that the experts in the various disciplines involved have little understanding of each other's subject, is a blast of ten air changes per hour distributed to every crevice in the shelving in an almost uninhabited, thickly insulated, vast building, crammed with temperature and humidity buffering treasures. After two years of measurement one can often reduce the air circulation rate close to nothing with no adverse effects other than the risk of rust in the climate machinery.

Few museums are rich enough to enjoy the over-equipping described above. The question more often is: Can we with a good conscience use this ancient, abandoned and derelict warehouse for storing the museums treasures? Sometimes the warehouse on offer is a half buried military store.

Sometimes the climate investigation is for a quite different purpose: why are the wall paintings flaking in this church?

The extra dimension in all climate studies of buildings that are not forcibly air conditioned is the outside climate. The outside climate should be measured at the same time as the inside climate, for at least three months and preferably for a year.

If you plan to rely on official climate records for the outdoor data you may be surprised by two things: the cost may be much more than the installation cost of sensors and the effort of massaging the data format into correspondence with your own measurements will exceed the time used in making your own weather station.

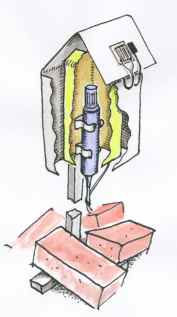

The only requirement for weather stations for our purpose is that they let air over the sensors while excluding rain and radiation. The device sketched here will hardly gain you a reputation for precision science in the game of global warming research but it will serve. I recommend a commercial RH transmitter for outside measurements. Vaisala and Rotronic are commonly used. Those sensors that can be bought, or made, for building into home made circuits seem not to be too good at resisting fog and frost without irreversible change in their characteristics.

The weather station is made from aluminium sheet, cut and bent. The outermost surface is painted white. The ventilation at the top should be protected by mesh to prevent birds nesting. The sensor is just clipped in place to allow removal for recalibration, needed quite frequently for outside sensors. The stalk is aluminium extrusion. Connections between stalk and shields should be with bolts fitted with washers to hold the metals apart and reduce heat transfer. A double shield is a luxury, but it is actually easier to make a rain proof, ventilated enclosure with two layers. The assembly should be exposed with the radiation sensor facing south. If radiation is not measured, the weather station should be in a shaded, north facing place (reverse these instructions in the southern hemisphere).

It is sometimes useful to measure other things than temperature and relative humidity. Radiation heating of dark roofs is a potent cause of mysterious condensation phenomena (see a previous chapter on condensation in museum buildings). High precision is not necessary here - a blackened exposed thermocouple, maybe with a transparent wind shield on windy sites, will certainly reveal if the sun is shining.

Times of wetness may be a useful thing to measure in connection with the source of water in damp buildings. This is surprisingly difficult to measure. Published, and sold, designs usually use a wettable, non conducting, plastic plate printed with interlocking combs of electrodes in two metals, gold and copper in the "Sereda" model. When a drop of water covers both metals a cell is formed which generates a detectable voltage. The problem in my experience is that the plastic soon becomes hydrophobic, presumably through deposition of greasy air pollutants. The plate will then not give a positive signal even in heavy rain, because the drops immediately run off, leaving a dry surface between the metal fingers.

Data loggers that can send out a voltage pulse can detect wetness on plates coated with interlocking electrodes of copper alone. The copper dissolves enough to make a conductive path through the water layer. These sensors are easy to make because copper coated plastic is sold for making electronic circuit boards. The copper can be cut, or etched away to make the electrode pattern. These sensors are also good for detecting floods.

Placing sensors in historic buildings

This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.