|

Low energy climate control - 4 |

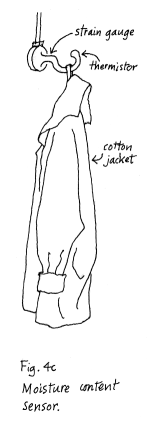

The purpose of relative humidity control is not really to hold a constant RH

but

to hold a constant moisture content in hygroscopic materials. A constant RH

almost implies a constant moisture content, but not exactly, as Fig. 2C shows.

It is more rational to hold the room's contents to a constant moisture content

by installing a sensor that measures moisture content directly, by weighing a

piece of hygroscopic material. One must also measure the temperature. From these

two values the ideal water content of the air can be predicted, and therefore

its dewpoint temperature. If a slow stream of outside air is pumped in over a

cooling coil at this temperature the room atmosphere will be in perfect

equilibrium with the objects. If the room temperature is close to the average

outside temperature the necessary dew point will nearly always be below that of

the outside air. Humidification will not be necessary. The air flow need only be

large enough to compensate for water gain through leakage and diffusion. The

heat generated in the refrigeration equipment can be reinjected into the air

stream. The method uses little energy in comparison with methods that involve

heating the air (7).

The purpose of relative humidity control is not really to hold a constant RH

but

to hold a constant moisture content in hygroscopic materials. A constant RH

almost implies a constant moisture content, but not exactly, as Fig. 2C shows.

It is more rational to hold the room's contents to a constant moisture content

by installing a sensor that measures moisture content directly, by weighing a

piece of hygroscopic material. One must also measure the temperature. From these

two values the ideal water content of the air can be predicted, and therefore

its dewpoint temperature. If a slow stream of outside air is pumped in over a

cooling coil at this temperature the room atmosphere will be in perfect

equilibrium with the objects. If the room temperature is close to the average

outside temperature the necessary dew point will nearly always be below that of

the outside air. Humidification will not be necessary. The air flow need only be

large enough to compensate for water gain through leakage and diffusion. The

heat generated in the refrigeration equipment can be reinjected into the air

stream. The method uses little energy in comparison with methods that involve

heating the air (7).

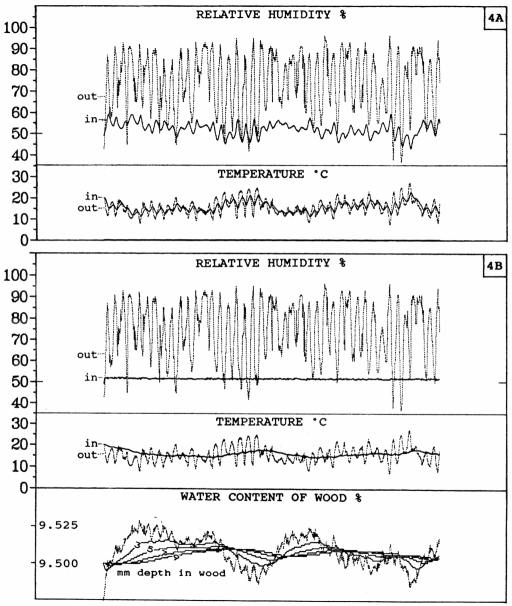

This method is not particularly effective in the lightly loaded room (A) because the daily temperature change is too fast for effective buffering. In a heavily loaded room (B) the method works perfectly.

Many collections contain objects or packing materials which release corrosive gases. The low temperature will retard the process but it may be necessary to include filters in the recirculation system because the ventilation rate is too slow to flush the room effectively.

This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.